If you’ve ever bent metal, you know that it can be tricky. Coils of sheet metal are heavy and unwieldy, so getting a consistent bend can be tough. If you’re looking for a more efficient way to get your jobs done, let us help! Here at Sheet Metal Benders Inc., we offer professional sheet metal bending services that will meet all of your needs.

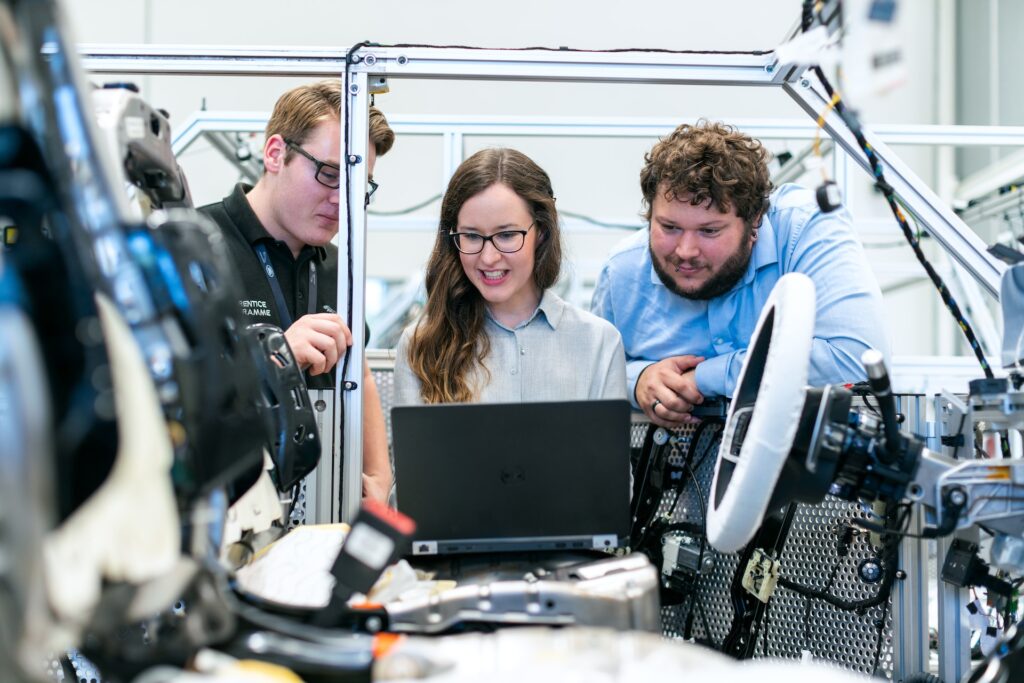

With the right equipment and a highly trained team, you can produce as many bends and angles as you need

- With the right equipment and a highly trained team, you can produce as many bends and angles as you need.

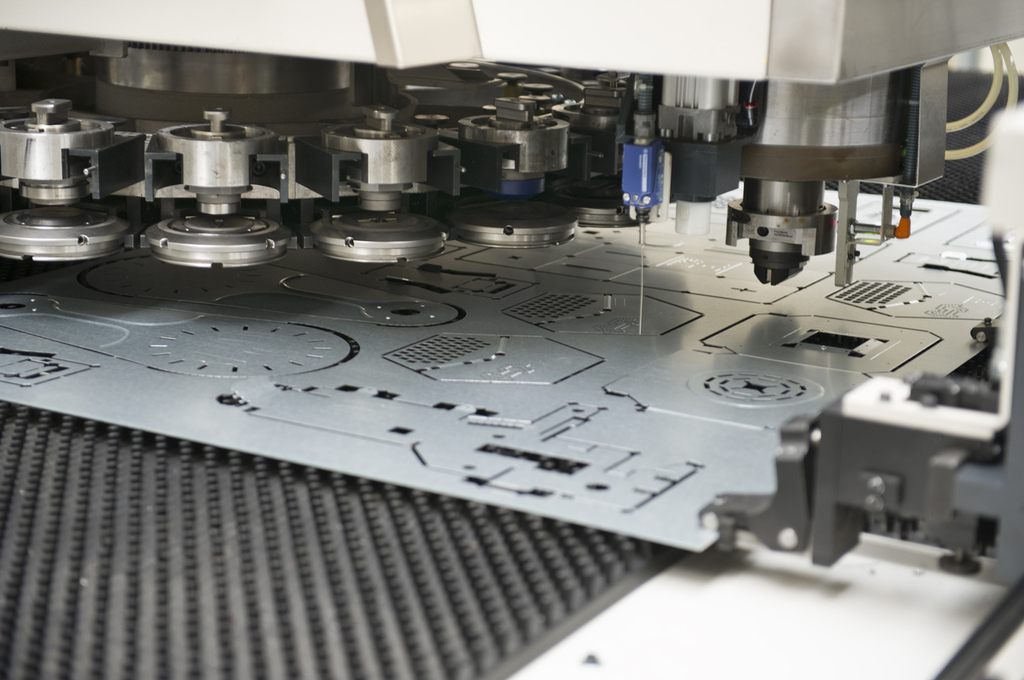

- TRIMAP International has a large number of different machines that can be used for bending sheet metal. These include:

- Bending rolls with capacities up to 6500mm (25ft) diameter or 24000mm (80ft) long;

- Sheet metal presses with a maximum force of 1000 tons;

- Sheet metal guillotines with cutting speeds up to 10m/s (33 ft/sec).

TRIMAP International is a professional sheet metal bending service that has been on the market for more than 35 years.

TRIMAP International is a professional sheet metal bending service that has been on the market for more than 35 years. We have a highly trained team, and we use state-of-the-art equipment to produce as many bends and angles as you need.

If you are looking for a reliable source of sheet metal bending services in your area, then look no further than TRIMAP International.

Bending metal takes a lot of experience, as well as specialized machinery designed to handle different metals and thicknesses.

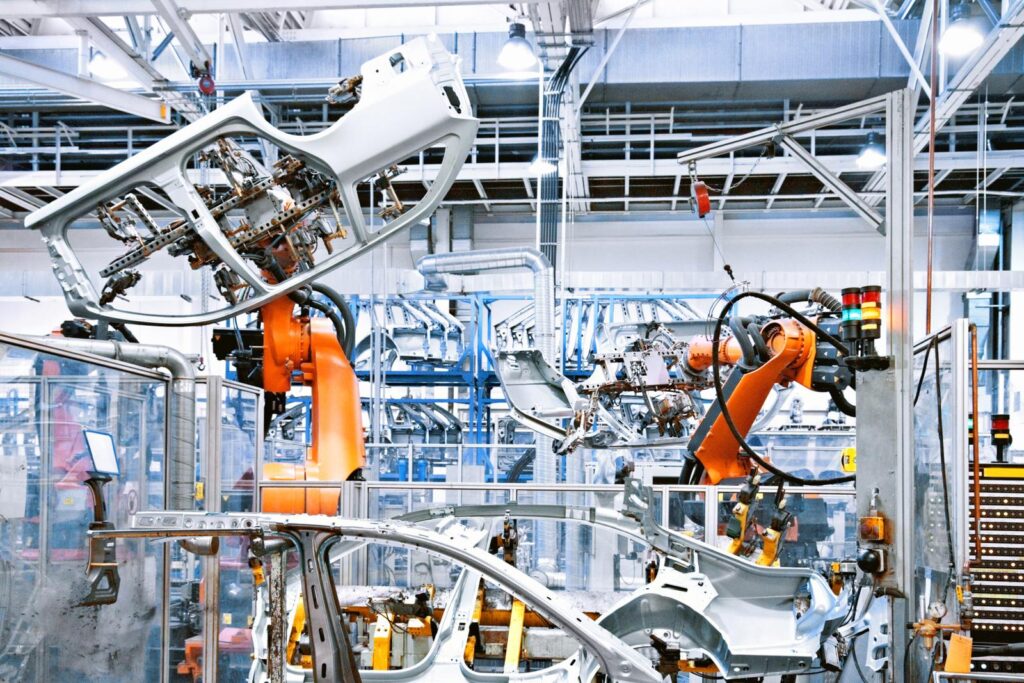

Bending metal takes a lot of experience, as well as specialized machinery designed to handle different metals and thicknesses. The most common metals you’ll see in sheet metal bending are steel and aluminum. Steel is often used for more heavy-duty applications such as vehicle frames, while aluminum is used when weight is an issue or if corrosion resistance is desired (such as for food packaging).

Bend radius refers to the amount of curvature that can be achieved during the forming process. A smaller bend radius means more extreme bending capabilities–but also makes it harder for your machine operator to achieve that degree of curvature.

TRIMAP International is capable of bending metal in different ways, depending on your design goals.

TRIMAP International is capable of bending metal in different ways, depending on your design goals.

Press Brake Bending: This method uses the force of a press brake to bend metal around an object. It is one of the most common methods used by fabricators and can be used for many different applications including making headlights or specialty parts out of sheet metal.

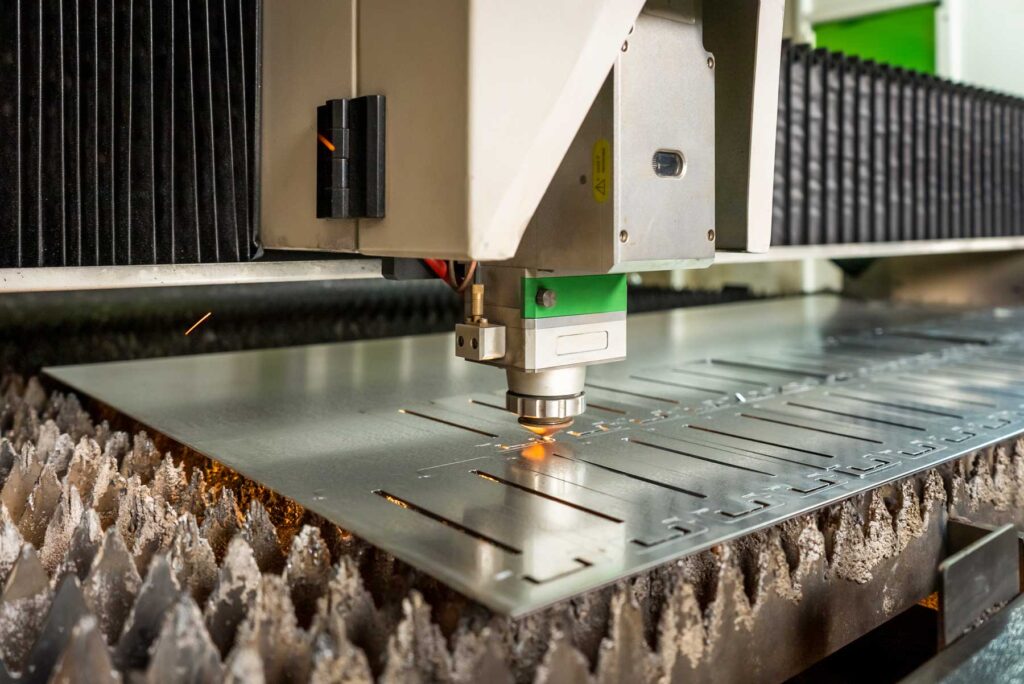

Laser Cutting: Using cutting tools like lasers and water jetters, TRIMAP International can cut pieces from thin-walled tubing at precise angles and lengths for any project you have in mind.

One of the most commonly used metal bending services is press brake bending.

One of the most commonly used metal bending services is press brake bending. A press brake is a machine that bends metal, and it can be used to create precise shapes for all kinds of purposes. The most common example is making sheet metal parts for cars or trucks.

Bending metal with a press brake takes time, but it’s not complicated once you know how the process works. Before we get into how long it takes to make a bend using this method, let’s take a look at some examples of things that can be done with this type of bending service:

Press brake bending is ideal for regular shapes like boxes, cylinders and cones.

Press brake bending is ideal for regular shapes like boxes, cylinders and cones. It can be used to make straight bends, angled bends and compound bends. Press brake bending also works well with flat sheets, tubes and other shapes. With this type of equipment you can make very close-fitting bends that are difficult or impossible with other methods.

Laser cutting is often used along with press brake bending to create precise shapes out of thin metal sheets.

Laser cutting is often used along with press brake bending to create precise shapes out of thin metal sheets. The laser beam cuts through sheet metal quickly, creating clean edges and sharp corners on the piece of metal being worked on. This allows for the creation of intricate details in your design without having to go back and repunch them into place with a punch or die. Laser cutting can also be used as an alternative method for cutting out shapes from larger pieces of sheet metal before they’re bent into their final form by a press brake machine.

Extruded aluminum, steel, brass and other metals are bent using our CNC bender.

A CNC bender is a computer-controlled metal-bending machine that uses a variety of tools to create complex shapes in metal. It can be used to bend sheet metal with tight radii and thin walls, which are difficult to achieve with manual methods.

The most common type of CNC bender uses hydraulics to apply pressure between two dies that are clamped together by rollers or slides. The dies are made from hardened steel, which makes them durable enough for repeated use without wearing out quickly like other types of dies do when used repeatedly over time (i.e., stamping dies).

The hydraulic pressure pushes against one die while pulling against another using two cylinders; this causes both sides’ surfaces to deform simultaneously so they meet at exactly 90 degrees each time you make an adjustment on your machine’s controls panel–no matter how many times you may need them adjusted before achieving perfect alignment.

If you're looking for a tight bend radius with thin-walled tubing, we offer mandrel tube bending services to produce precisely-formed shapes.

If you’re looking for a tight bend radius with thin-walled tubing, we offer mandrel tube bending services to produce precisely-formed shapes.

Our mandrel benders can handle a variety of materials and sizes. We use the right tool for the job so that you get everything done quickly and accurately.

The process that are performed in order to make a good bend every time.

- Cutting: The first step is to cut the material to the desired shape and size, which can be done with shears or other industrial tools. Once you have your piece of sheet metal cut out, it’s time to move on to the next stage.

- Bending: This is where your handiwork comes into play–it’s time for you (or one of our highly trained professionals) to bend the sheet metal into whatever shape or curve you need it for your project. Our experts use specialized equipment like brakes and rollers as well as their own strength when bending large pieces like car bodies; however smaller items like hinges can also be bent manually by hand if needed. Remember: Good bends start here.

Conclusion

If you’re looking for a professional sheet metal bending service, TRIMAP International is the company to call. We have been serving our customers since 1983 and have built up a reputation as one of the best companies in our industry. Our team has decades of experience working with different types of metals, so whether you need your pipes cut or bent into shape with precision accuracy–we can do it all!