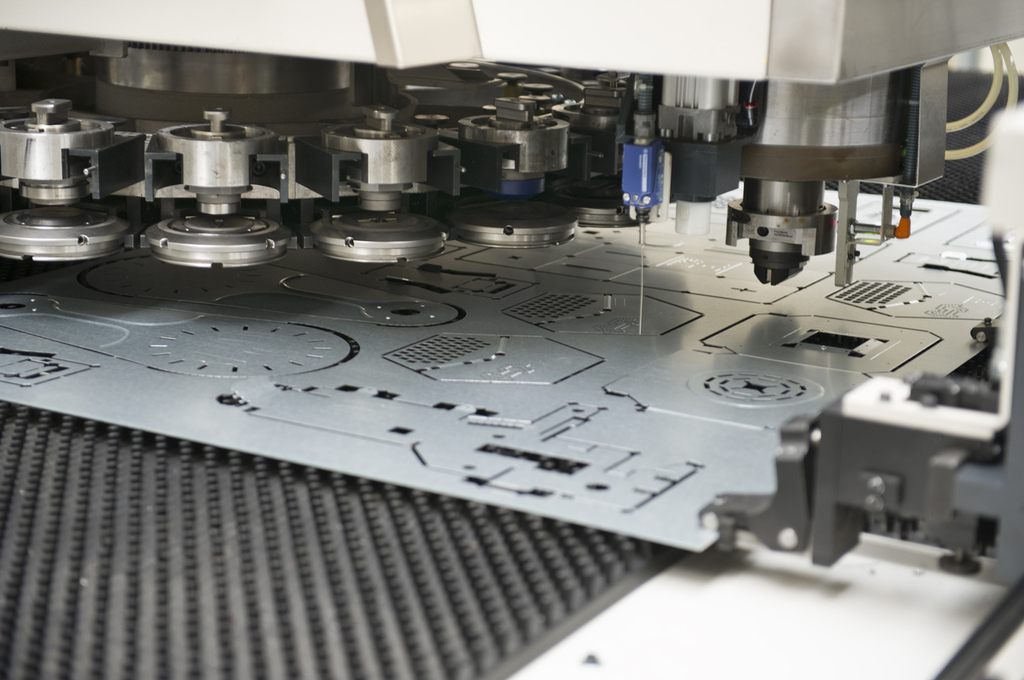

Sheet metal is a flat, thin piece of metal that you can use for many different purposes. The piece needs to be cut out in order to make it into something useful or functional. Sheet Metal CNC punching machines are used to create the holes needed in order to complete the task at hand. This article explains what sheet metal CNC punching is and how it works.

Sheet Metal CNC punching is a process used to create an opening or hole in sheet metal.

Sheet metal punching can be done by hand, but it is time-consuming and not as accurate. A CNC punch press allows you to quickly and accurately create holes in sheet metal, saving you money on labor costs and improving your product quality.

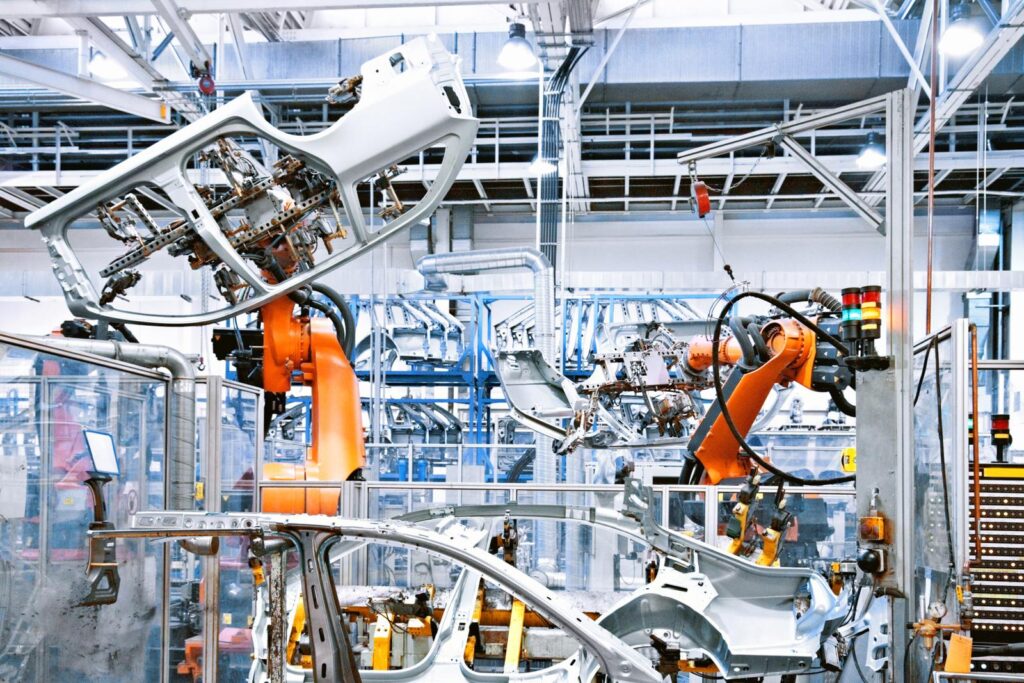

. Sheet metal can be cut or formed into a variety of shapes and sizes, which makes it useful in many industries.

For example, sheet metal is used in the construction industry to create structural components such as roofs and walls for buildings. It’s also used as an insulator for electrical wiring and plumbing pipes because it conducts heat well but not electricity or water vapor

A punch press uses a punch to cut out the shape that was programmed into the machine's computer software.

The hole punch machine will punch the desired shape out of the sheet metal material in one pass, making it easy for you to get your job done quickly and efficiently.

The hole punch machine will punch the desired shape out of the sheet metal material in one pass.

A sheet metal CNC punching machine is a mechanical device that can be used to punch holes in sheet metal. The machine will punch the desired shape out of the sheet metal material in one pass, instead of requiring multiple strokes to cut through it like a traditional punch press would do.

The punch press will do this by using hydraulic pressure to ram its chisel against anvils at high speeds, producing thousands of pounds per square inch (PSI). This force allows you to make clean cuts without any burrs or rough edges left behind on either side of your finished product

When this process is done correctly, it creates the most consistent and accurate holes in a sheet of material.

The sheet metal CNC punching process creates a precise hole in your sheet metal workpiece

The sheet metal CNC punching process creates a precise hole in your sheet metal workpiece. The hole can be round, oval or rectangular and can range from as small as 1/8″ (3mm) to over 8″ (200mm). Sheet metal is any flat piece of metal that has been formed into an appropriate shape for its intended use.

A punch press uses a punch to cut out the shape that was programmed into the machine’s computer software by an operator or engineer..

Conclusion

The CNC punching process for sheet metal is a great way to create precise holes in your workpiece. This process will give you consistent results every time, which is important if you need to make sure that every part fits together perfectly. The best part about this process is that it doesn’t take long at all! For more information please visit https://trimap.co/.