What is a chassis?

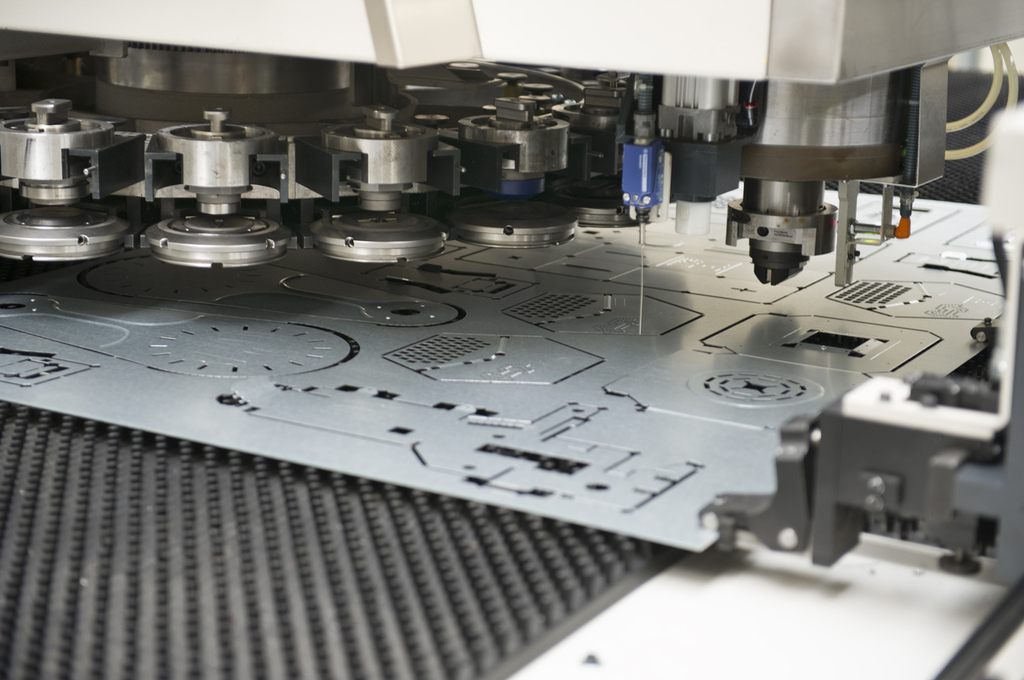

Chassis design is the process of creating a protective shell for hardware. This shell can be made of plastic, metal, or other materials and serves two main purposes: to protect the internal components from damage and to serve as a base for attaching other components.

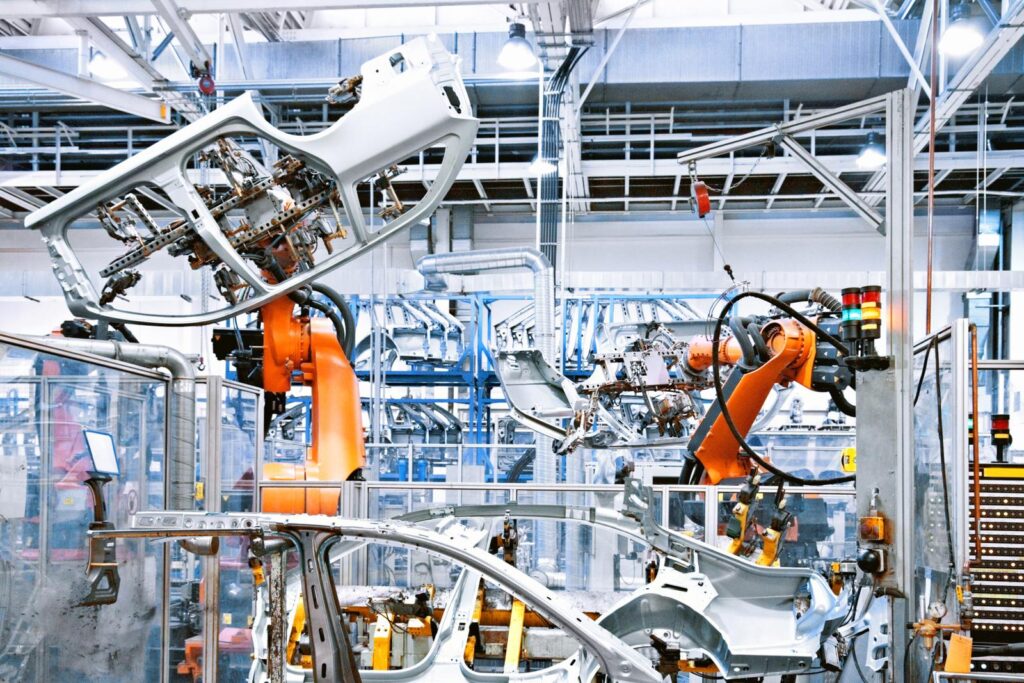

Chassis designs can be found in all types of devices, including computers, cars, airplanes and more. Everything from your desktop PC tower to a rocket ship will have some sort of chassis design.

The chassis of a piece of hardware is basically its outer shell.

Enclosure design gets more involved with PCB design, because the enclosure must protect the printed circuit board inside from anything that might damage it.

You might be wondering, “Enclosure design is important, but why?” There are four main reasons why it’s so critical:

The enclosure must protect the PCB from anything that might damage it. The enclosure should prevent anything from entering the interior of your product and causing damage to the circuit board inside. This could include moisture, dust, or other contaminants such as electromagnetic interference (EMI) or electrostatic discharge (ESD).

The enclosure must protect the PCB from physical damage. Your product needs to have an outer shell that will keep it safe in case of drops or falls; if this shell cracks or breaks open when dropped onto a hard surface such as concrete then your product will no longer perform its intended function correctly due to internal damage caused by impact with outside forces like gravity acting upon its mass during free fall in Earth's gravitational field—this means that protective cases need extra padding around any openings so nothing can sneak through them!

What are the different types of enclosures?

Chassis

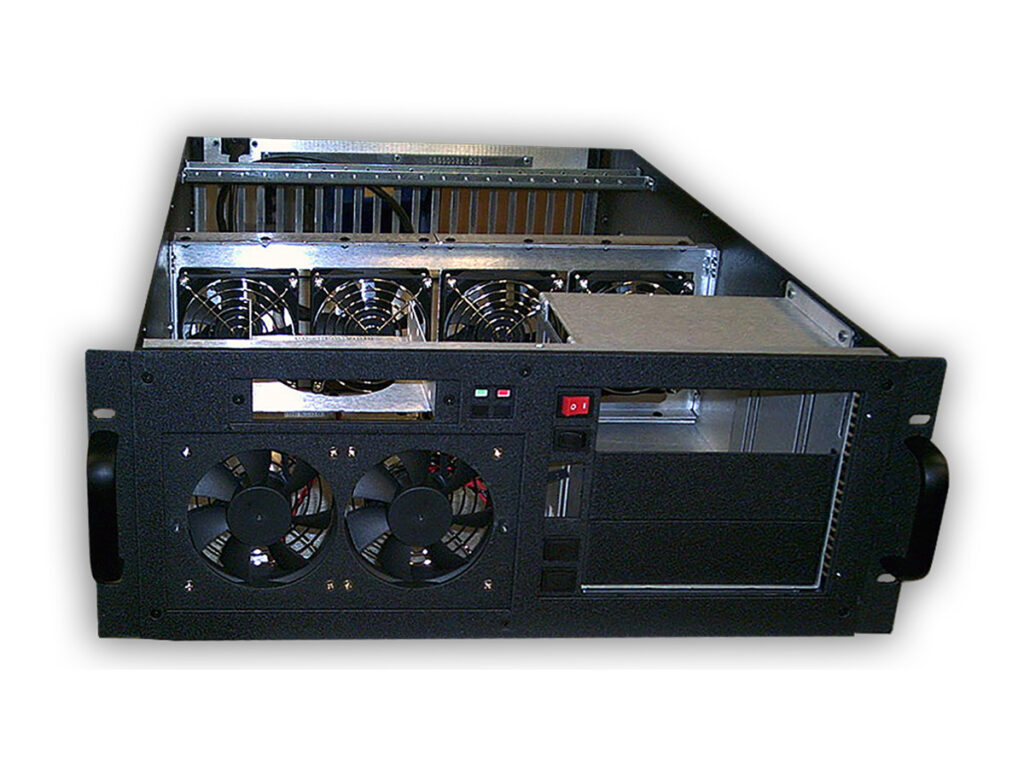

A chassis is a metal enclosure which houses printed circuit boards (PCBs) and other electrical components as well as providing mechanical support and protection to those components. Chassis can be made of various materials like steel or aluminum alloy, plastic or even fiberglass composite materials like FR4 PCBs that have been enclosed within an outer shell or case with all necessary ventilation openings located at strategic locations to allow heat dissipation from sensitive components inside while preventing foreign objects from entering without damaging critical areas or disrupting operation of equipment running inside them (eBay).

Boxes

Boxes are often used by hardware manufacturers because they provide better protection against hazards such as dust than either cases or shells do alone on their own; however, if exposed to extreme conditions such as high temperatures then this may not always be true because it is difficult for any material except for metal ones like steel which conducts heat very well but also increases weight significantly (eBay).

Why does chassis design matter?

You’re a hardware manufacturer. You know that your product appearance is important, but you might not understand why enclosure design is so crucial to the success of your project. The enclosure, or chassis, is an integral part of your product and can make or break its performance in the market.

A well-designed chassis will improve your company’s reputation for quality products and contribute to customer satisfaction by providing a pleasing experience with every purchase. Chassis design isn’t just about aesthetics; it’s also about ensuring that your hardware works properly with all of its components and accessories—for example: PCBs (printed circuit boards) have been designed to fit a specific size frame and are likely to be damaged if they’re forced into something too small or too large; power supplies need enough space around them so they don’t overheat; batteries must be protected from moisture damage etc…

Your product's physical appearance is one of the first factors a consumer will notice when they see it.

Your product’s physical appearance is one of the first factors a consumer will notice when they see it. The enclosure design should reflect the function of your product and not just be an arbitrary shape. A well-designed enclosure will take into account both its functionality and aesthetics since consumers often make purchasing decisions based on how a device looks as much as what it does.

A great product demands a great enclosure.

You may be familiar with the concept of product design as a holistic process in which all aspects of your product are developed together. This is because your product needs to look good and function well from start to finish. While you might think that enclosure design is just about how your PCBs will be packaged, it’s actually more than that.

The enclosure is the first thing customers see when they receive their order, so it’s imperative that it presents an appealing appearance that matches your brand’s personality and style. It’s also the last thing customers see before they use or dispose of their products—so even if there are problems inside, consumers won’t know unless they open up every product individually (which isn’t likely).

How can I get started with chassis design?

If you’re just starting out and want to get your feet wet with enclosure design, there are some things that you can do to make sure you’re headed in the right direction.

One of these is using an appropriate design tool like AutoDesk Fusion 360 or Solidworks. These programs give you the ability to model your enclosure, as well as simulate its performance in various environments (like temperature or shock). You may not know how or where your enclosure should be manufactured yet, but being able to see what it will look like before committing yourself is important for getting feedback from different sources on whether or not it will work for them.

Another thing you can do is start with a simple design first—then add complexity when you feel more comfortable designing enclosures yourself! There are tons of online tutorials and books about this process available online if needed too!

Is there anyone who can help me out with enclosure design and manufacturing?

The next step is to find a manufacturer who can help you with your enclosure design and manufacture. It’s important that this person/company is qualified and experienced as they will be responsible for the overall success of your product.

If you have any questions about what we have discussed in this article, please feel free to contact us!

If you haven't thought about chassis or enclosure design, now's the time to start.

If you haven’t thought about enclosure design, now’s the time to start.

Chassis and enclosure design is important for hardware manufacturers because it influences many aspects of your product’s performance, durability and aesthetic appeal. Your customers will spend more time interacting with their device if its enclosure provides a pleasing experience. It’s also important that you consider your company’s brand identity when designing enclosures for hardware products since they’re often visible from across the room or from an online listing page.

By taking some time to research different types of enclosures available on the market and understanding how these can impact the usability of your product, you’ll be able to make informed decisions about which features are most important to achieve within your budget constraints.

So, if you’re looking for a new enclosure for your hardware, or even just thinking about what would be best for your product, then it’s time to get started. You’ll have more options than ever before with all the different materials and styles available on the market today. And with these tips in mind, you can get started designing an enclosure that will make your product stand out from its competitors—and look good doing it!