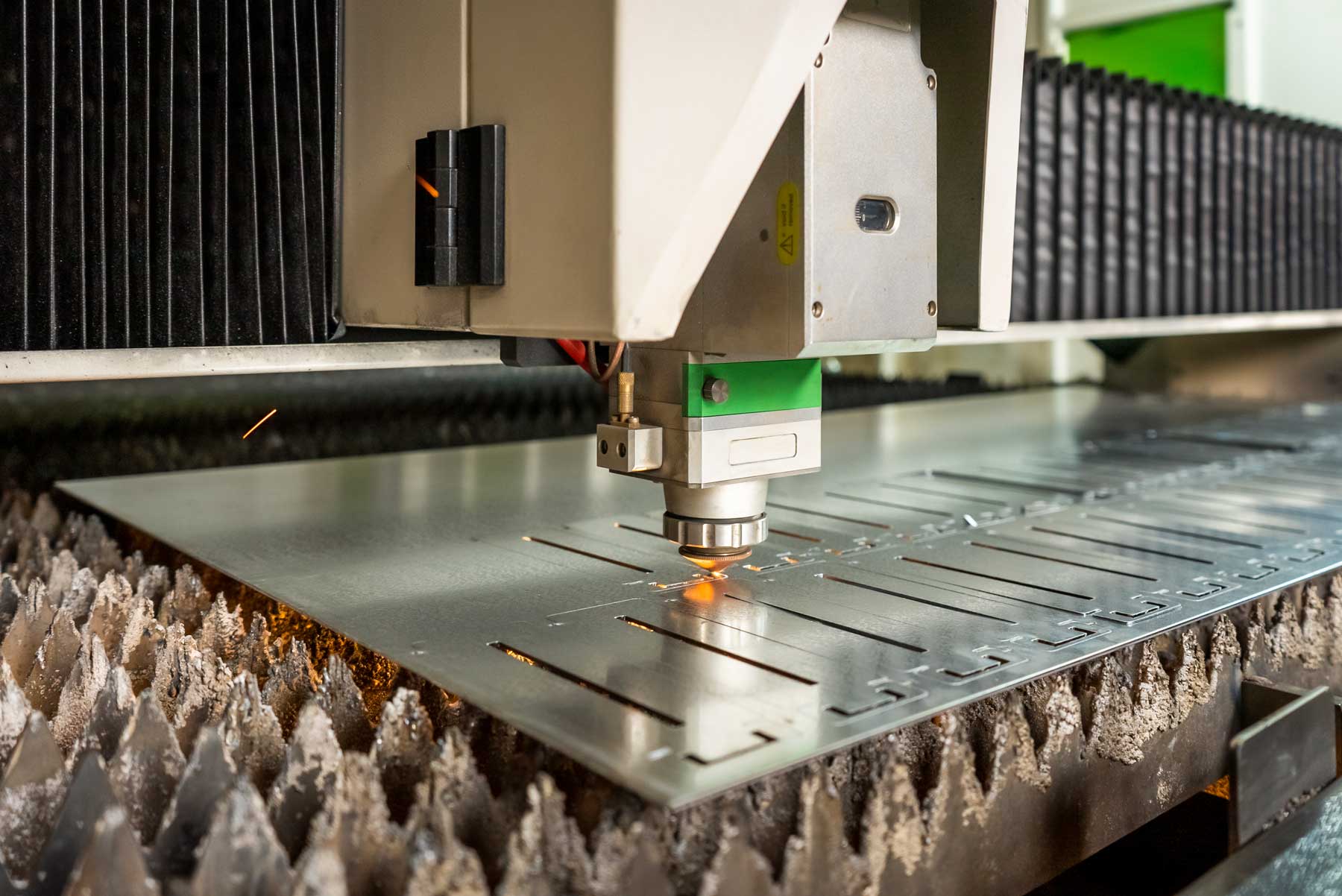

When it comes to chassis enclosure manufacturing, material selection is a critical factor that can significantly impact the overall quality, durability, and functionality of the final product. Choosing the right material is essential to ensure that the enclosure can protect electronic devices from various environmental factors, such as heat, moisture, and physical impact. In this article, we will explore the best materials for chassis enclosure manufacturing and explain why material selection matters.

Some of the Most Common Materials used in Chassis Enclosure Manufacturing

Aluminum

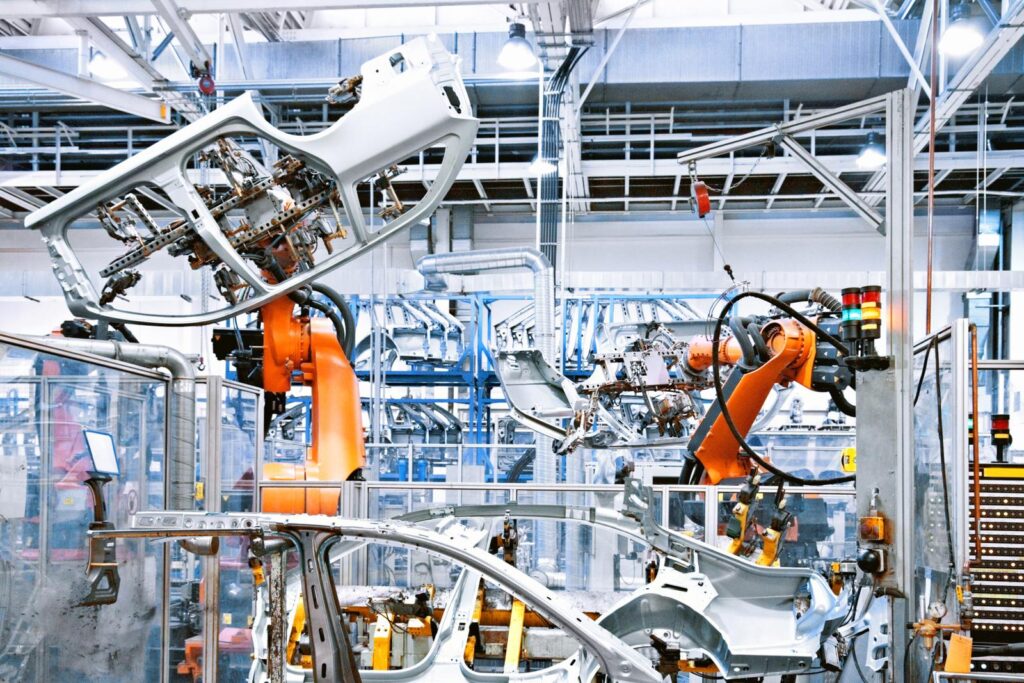

Aluminum is one of the most popular materials used for chassis enclosure manufacturing. It is lightweight, durable, and easy to machine, making it ideal for applications that require strength and rigidity. Aluminum enclosures are also corrosion-resistant and can withstand harsh environmental conditions. They are commonly used in industries such as aerospace, automotive, and electronics.

Stainless Steel

Stainless steel is another popular material used for chassis enclosure manufacturing. It is a corrosion-resistant alloy that can withstand high temperatures and harsh environmental conditions. Stainless steel enclosures are often used in applications that require strength, durability, and aesthetic appeal. They are commonly used in industries such as food processing, medical equipment, and marine applications.

Plastic

Plastic is a lightweight, low-cost material that is easy to mold and shape into various designs. It is an excellent choice for chassis enclosure manufacturing, particularly for applications that do not require high levels of strength or durability. Plastic enclosures are commonly used in consumer electronics, automotive, and medical applications.

Carbon Fiber

Carbon fiber is a lightweight, high-strength material that is ideal for applications that require maximum strength and rigidity. Carbon fiber enclosures are often used in aerospace, automotive, and sporting equipment industries. They are also commonly used in applications that require a lightweight yet strong structure, such as UAVs and drones.

Titanium

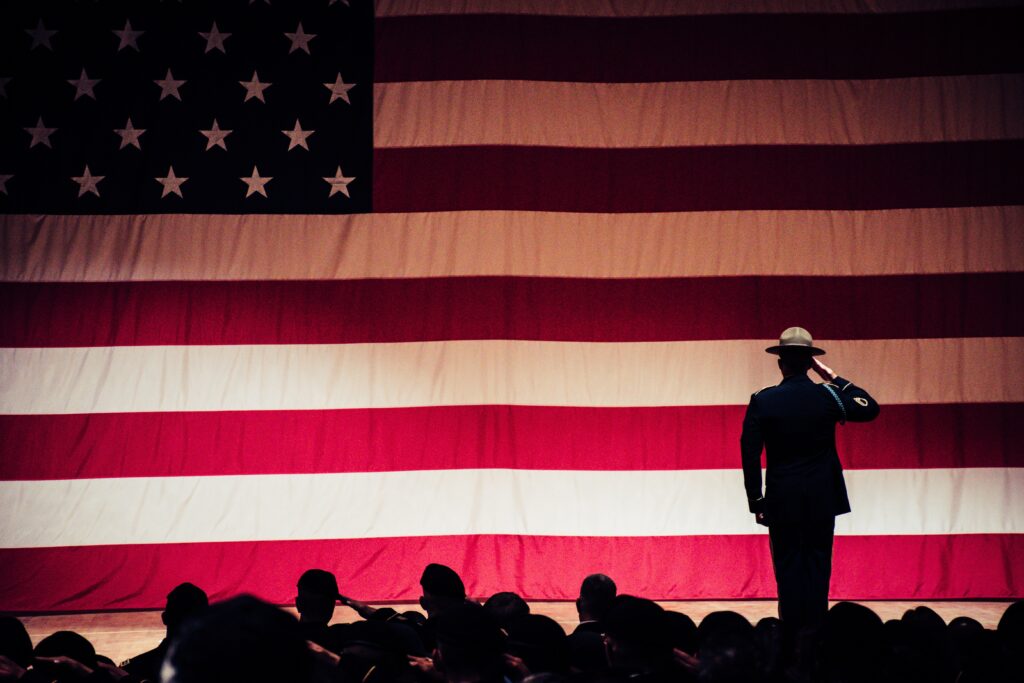

Titanium is a strong, lightweight material that has excellent corrosion resistance and high-temperature tolerance. It is ideal for applications that require high levels of strength and durability, such as aerospace and medical applications. Titanium enclosures are also commonly used in the military and defense industries.

Why Material Selection Matters

Material selection is a critical factor that can significantly impact the overall quality, durability, and functionality of chassis enclosures. Choosing the right material can ensure that the enclosure can withstand various environmental factors, such as heat, moisture, and physical impact. It can also determine the aesthetic appeal of the enclosure and its ability to protect electronic devices from electromagnetic interference.

Furthermore, choosing the wrong material can result in the premature failure of the enclosure and, ultimately, the electronic devices it protects. For example, using a material that is not corrosion-resistant can lead to rust and other forms of degradation, resulting in the failure of the enclosure and the electronic devices it protects.

In conclusion, material selection is a critical factor that can significantly impact the overall quality, durability, and functionality of chassis enclosures. Choosing the right material is essential to ensure that the enclosure can protect electronic devices from various environmental factors, such as heat, moisture, and physical impact. By considering the characteristics and requirements of the application, manufacturers can choose the best material for the chassis enclosure manufacturing.